After cleaning and testing injectors if the results are not perfect, some wonder if the injectors Ok to use? Understanding the reports is key and this guide will help.

For any engine management system using sequential fuel injection, tighter matching helps ensure each cylinder gets the correct air-fuel ratio. Here are the fundamentals; use this alongside your reports to guide your decisions when in doubt.

Injectors Will Do, What Injectors Will Do:

Port Injectors:

Injector Flow

-

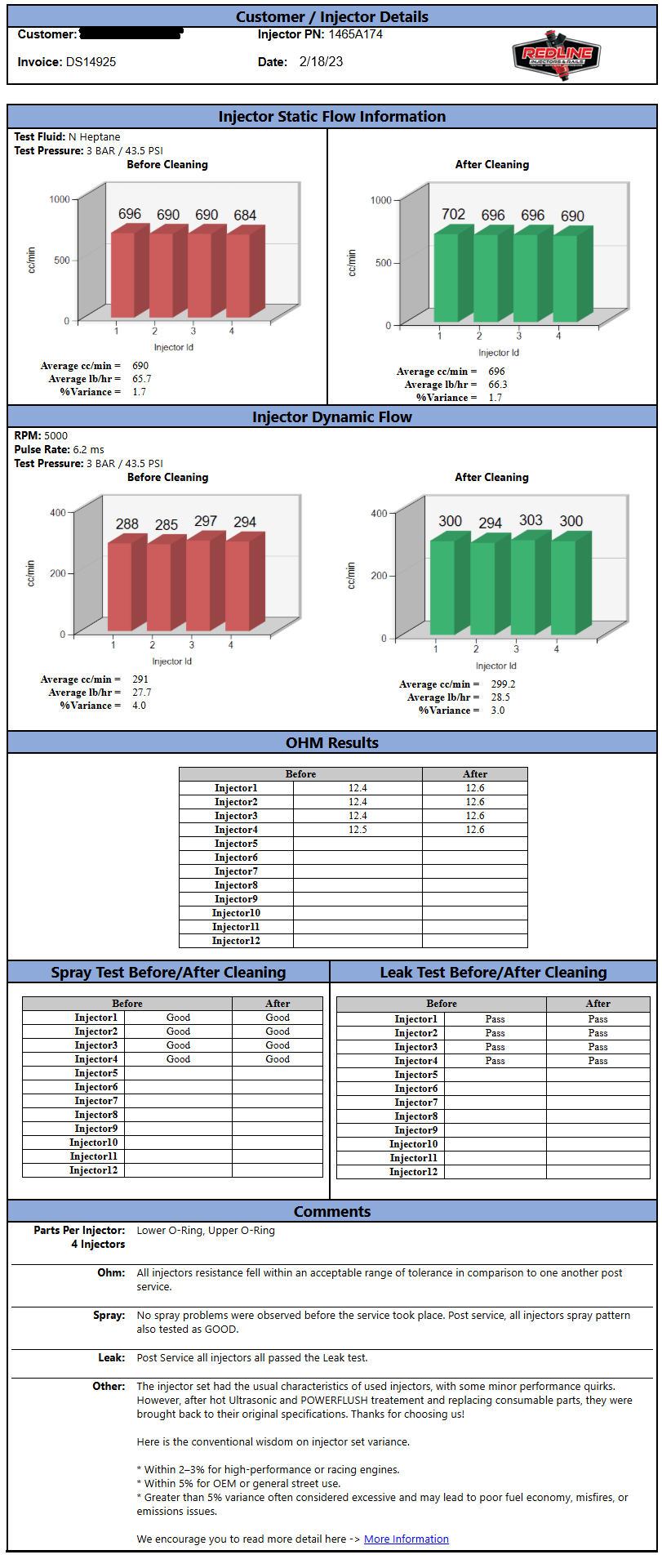

- Static Volumes (cc/min & lb/hr)

- Static flow is is the flow rate when the injector is energized and held open continuously (100% duty cycle).

- Static flow is a simple measurement of the maximum output of the injector at a given pressure.

- Static flow is often used as a benchmark for injector capacity and is commonly expressed in units like lbs/hr or cc/min.

- Static flow output volume is generally much higher than dynamic flow since it operates like an open hose with unrestricted flow.

- Dynamic Volumes ()cc/min & lb/hr)

- Dynamic flow measures the fuel flow rate when the injector is pulsed on and off, simulating the way injectors operate in a running engine.

- Dynamic flow is influenced by factors like pulse width (the time the injector is open during a pulse) and pulse frequency (the number of pulses per second).

- Dynamic flow testing is crucial for understanding how injectors perform under real-world operating conditions, including idling, acceleration, and deceleration.

- Dynamic flow is sometimes expressed in duty cycles, which is the percentage of time the injector is turned on during a pulse period.

- Dynamic flow output is significantly less than Static as the injector is pulsed

- Static Volumes (cc/min & lb/hr)

Flow Variance (Only applicable to Port injectors, GDI/Piezo have flow corridor reports)

- An acceptable average fuel injector flow variance across a set of injectors is typically:

Within 2–3% for high-performance or racing engines

Within 5% for OEM or general street use

- Breakdown:

0–2% variance: Excellent matching, ideal for performance tuning and consistent combustion.

2–5% variance: Acceptable for most OEM applications and everyday vehicles.

5% variance: Often considered excessive and may lead to poor fuel economy, misfires, or emissions issues.

Leak Testing

Injectors should not leak when closed under fuel system pressure.

A leaking injector can cause hard starts, flooding, or engine misfire.

Electrical Performance

The injector’s resistance (ohms) should be within manufacturer specifications.

Irregular readings can indicate coil failure or short circuits.

Spray Pattern (Only applicable to port injectors)

The spray pattern should be fine, even, and conical without distortion or heavy drips.

Irregular spray patterns suggest clogging or internal damage.

GDI Piezo Injectors:

- Small amount of the above is applicable to GDI/Piezo injectors; however understanding the test results is for these injectors is vital. Injectors are designed to operate within a specific flow corridor and things like spray pattern are meaningless. If your GDI/Piezo injectors show red for example, it does not mean they are not usable it depends how far outside the norm they are and the intended use. If they are far out side then it is perhaps best to replace them. What is too far? We do not say and can not say. It depends. See this post to go into further detail on GDI/Piezo injector reports.

Bottom Line:

- We do not provide recommendations on whether to use injectors after the service based on the results. Our role is to clean the injectors and present the test results. Based on those results, the customer can choose to either continue using the injector or replace them based on their needs and understanding. When an injector is clearly failed we will tell you. When an injector hasn’t failed but shows less-than-ideal performance in one or more tests, it’s up to the customer to decide how to proceed based on their specific circumstances.