- We do not ultrasonically clean your filters. Our standard service includes replacement of all filters, O-rings, pintles, seals, grommets, spacers, and related components; whether it’s Port Feed, Side Feed, E-TEC, GDI, or Piezo injectors.

- We do not offer no-parts or testing-only option not do we sell parts. Our service is provided exclusively as a single, premium-tier offering.

- Restore maximum power and OEM-level performance with our injector cleaning and testing service – For fuel injector service, go with Redline Injectors!

Premium Cleaning and Dynamic Testing of Port Injectors

Our Port Injector (PFI) Systems Cleaning and Testing Procedures

- Some tests may not be applicable for some injectors, for example, Static flow testing is non-operable on E-TEC injectors.

- We typically perform port injector flow tests at 43.5 PSI (3 BAR). However, some injector types require test pressures ranging from 20 to 90 PSI (1.3 to 6.2 BAR), depending on their specifications.

- For GDI and Piezo fuel injector testing requiring 2000–3500 PSI and manufacturer-specific procedures, please visit our Piezoelectric / GDI Injector Cleaning page.

- 1 Stage Exterior Hot Water Cleaning

- 1 Stage Hi-Pressure Air Flush

- Microscope Inspection

- Injector Numbering

- Solenoid Resistance Check

- Spray Pattern Analysis

- Static Flow Test (Volume)

- Dynamic Flow Test (Cruise RPM)

- Strip Injectors

- 2 Stage Hi-Temp Ultrasonic Cleaning

- 1 Stage Optional POWERFLUSH Reverse Cleaning

- 1 Stage Low Pressure Air Backflush

- Media Blast (pitted and corroded metal injectors bodies will be media blasted)

- We do not paint injectors after media blasting, the customer has the option to do so.

- We use N-Heptane Calibration fluid following Bosch and Siemens recommendations for port injectors

- Leak Down Test Incremental 40-100 psi

- Spray Pattern Analysis

- Static Flow Test (Volume)

- Dynamic Flow Test (Fast Cruise RPM)

- Internal Lubrication

- Capped to Avoid Damage

- Before/After Report as Applicable

Premium Fuel Injector Cleaning And Dynamic Testing for Port Injectors

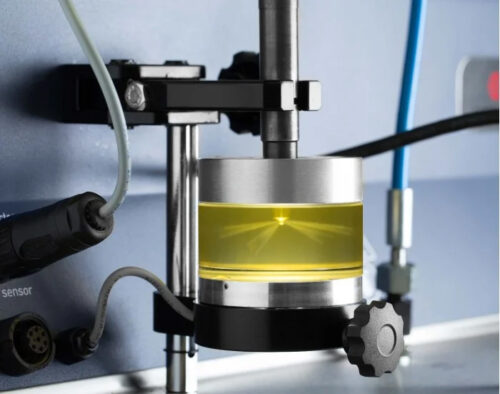

From Auto to Marine; we use the latest Zapp GS8 to accurately test whether your port injectors are operating within the required tolerances. Our port injector service always include BOTH Static and Dynamic tests.

- If an injector is found to be permanently defective, we will not proceed with the service. Instead, we will issue a refund for the cost of the injector, minus a $5 bench fee.

- Our fuel injector cleaning and testing service includes up to six cleaning steps, including a POWERFLUSH stage when needed for stubborn injectors. This approach can greatly enhance the outcomes compared to conventional ultrasonic cleaning methods alone.

- Our Port fuel Injector tests are all carried out on the latest Carbon Zapp machines.

- As part of our premium service, you will receive new fuel injector components, including filters, O-rings, seals, caps, grommets, clips, spacers, decouplers, clamps, ferrules, caps and hoses, with OEM options generally available for all injector types.

- We include a Color Injector result report with all our injector service options shown below.

- Please note that some parts for certain injectors may occasionally be on back order, and we will inform you if this occurs.

- We capture video snippets of your injector flow tests and send them to you as the work progresses.

Service Exclusions

- We do not service Diesel Injectors.

- We do not service for GM CPI/SCPI Spider injectors.

- We do not service FICHT injectors.

- We do not service Flux Capacitors

- See our Injector ID Page for visual references.

Shipping and Service FAQs

Service Related Questions

Our standard injector service includes an additional POWERFLUSH cleaning stage for Top Feed, Side feed, E-TEC, Optimax Air, GDI and Piezo Injectors.

Yes, we have a 2 injector minimum.

Absolutely! Rest assured that we will take care of removing the injectors for you for (typically GDI and side feed) and invoice you for a bench fee of $10 per rail to do the work as problems can often arise. However, it’s important to note that we cannot be held responsible for any potential damage that may occur during the removal process. To ensure a smooth experience, we recommend that you personally remove the injectors from the rail.

To avoid any issues with shipping service secure them in plastic and tape them to prevent leaks.

For your convenience, side feed injectors will be re-installed in the fuel rails, top feed and GDI injectors will be packaged separately. GDI Injector clips are very easy, you’ll have no issues, but they are tricky to get off which we will do if you wish.

- Service prices and options are posted in store per item type as well as on the pricing page. Service Pricing

- Please check the Injector id injectors page on the menu if your unsure what you have. Injector ID

Turn around times are stated on the Home page.

Shipping Related Questions

For local drop/pick up service check the “Local Drop-Off” box on the order form.

Once order is places, email us at [email protected] for drop off instructions.

- Shipping insurance up to $100 is automatically provided.

- To add Shipping additional Insurance, please select amount coverage you’d like using the “Shipping Insurance” line item before checkout.

- Additional shipping insurance is calculated for you based on $1.60 per $100 of declared value.

- Please insure items based on their actual replacement value, extra insurance above the value will accomplish nothing, claims are on shipment value, not amount of insurance bought.

- Insurance applies only to the item we’re returning to you.

If you would like expedited shipping contact us at [email protected] for separate invoicing for those charges. Once the items are packaged and ready to ship we will send a separate invoice for the chares based on the option you specified.

Remember to enclose a copy of the “order receipt “inside the package you are sending to us.

We accept shipments from UPS, USPS, Fedex or DHL to following address 7 days a week.

Sending UPS is the optimal choice within the US, however.

Redline Injectors

3036 HIGHWAY 35 #227

Hazlet, NJ 07730

Remember to enclose a copy of the “order receipt “inside the package you are sending to us.

When preparing the injectors for shipping, it is strongly advised to place them inside a regular zip lock bag first. This will help to keep the fuel smell contained. It is important to avoid any damage during transit, so make sure not to simply toss the bag into a box without any additional packing material. This is particularly crucial for the pintle end.

It is not recommended to ship the injectors in a bubble envelope. Optimal protection can be achieved by using a box with some padding or a bubble envelope in a box. The small flat rate box from the Post Office may be good budget-friendly option for smaller injectors.