We take pride in providing a premium service that goes above and beyond. As the market leader in premium injector services, we offer expert Fuel Injector Cleaning and Testing with unmatched precision and quality. Serving the US, we ensure a rapid service turnaround so you can motor with confidence.

Get Premium Fuel Injector Cleaning Today

An Engineering-Based Approach To Fuel Injector Service

Redline Injectors was started by engineers and run by engineers, at the core of our commitment to quality and an engineering-based approach. We use multiple injector test machines machines, each designed for specific injector type – because no single machine can properly handle every injector.

You’ve probably seen YouTube videos of shops using hammers, screwdrivers, and rusty makeshift tools on injectors and rails. That’s not how we operate. If our equipment doesn’t support a specific need, or if an injector requires some adapters or if a tool is needed, we design and manufacture it.

Because of our additional processes, meticulous handling and additional cleaning steps, it takes us longer to complete a set of injectors compared to most shops, so we limit the number of orders we accept weekly to maintain turnaround time and ensure maximum quality.

Our Equipment and Partners

We Exclusively Use Fuel Injector Test Machines From

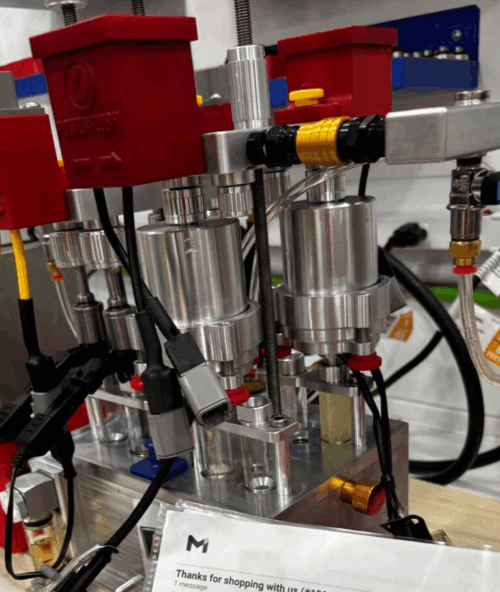

We are based in New Jersey, where we proudly source the latest Carbon Zapp Multi-Port and GDI & Piezoelectric testing equipment, Elma ultrasonic machines. We design and create our own custom tooling and cleaning machine and source machine shop services from top-tier vendors. Whether CNC billet aluminum or SLS 3D glass filled 3D printing, this ensures our our manufacture of proprietary equipment and tooling adheres to the highest industry standards.

Every tool or machine we design is CNC machined to exact tolerances. Often many variants of them with slightly different dimensions for various injectors.

The cost of a tool is never a factor in our decision-making process when determining whether to create one. If a tool is needed, then it should properly exist; it’s as simple as that. This is yet another factor that distinguishes us from our competitors.

Propriety Precision Reverse Cleaning Technology

We also design in CAD and custom-build propriety machines for fuel injector reverse cleaning utilizing nitrogen-based detergents from BASF. These machines are exclusively designed and manufactured for us, by us, for our use. For more details, please visit our POWERFLUSH page.

Redline Injectors Custom Tooling Example

In our shop, you won’t find makeshift solutions; we avoid using improper tools at all costs. When we identify a need for a new tool, we proactively design and create it ourselves, even if seems excessive or un-necessary by others.

For instance shown below, when working on this customer’s 599 GTB Fiorano fuel rail and injectors, we needed spacers to properly fit our POWERFLUSH system for fuel injector cleaning—before even beginning the cleaning process or removing the injectors from the fuel rails.

Premium Nylon Injector Spacers

Rather than using metal washers, nuts, or other device we find laying around that could potentially cause damage the injector seats that are not replaceable, we designed custom concave spacers and had them made from glass-filled Nylon 12. These spacers were specifically crafted to fit these injectors within our POWERFLUSH cups to prevent damage during compression when cleaning them.