Don’t settle for just cleaning the spray tips – Redline Injectors also cleans the inside of your fuel injectors for a deeper, more complete clean. Choose Redline Injectors for fuel injector cleaning services.

Redline Proprietary Fuel Injector Cleaning

Refurbish and Restore Fuel Injectors

Gasoline fuel injectors are sealed units and cannot be “rebuilt” strictly speaking. Rebuild of fuel injectors for gasoline engines typically refers to cleaning and relacing consumable components. However, they can be ultrasonically cleaned, and components such as O-rings, seals, spacers, and protective caps can be replaced to restore their sealing functionality. At Redline Injectors, in addition to traditional pulsed hi-temperature ultrasonic cleaning of injector tips, we additionally perform a comprehensive internal fuel injector cleaning with our proprietary POWERFLUSH machine which thoroughly cleans the injector internally—not just at the tip. This helps further restore the fuel injector’s flow performance. Combined with replacement of consumable parts such as O-rings, filters, pintle caps, seals, spacers, and grommets, we can refurbish the fuel injectors to near-new condition and restore their original functionality.

While not every injectors fits most do, so whether you have older port or modern GDI injectors that are not worn, Redline Injectors can refurbish, restore and renew fuel injectors to peak performance!

Proprietary Fuel Injector Reverse Cleaner

Home of the POWERFLUSH

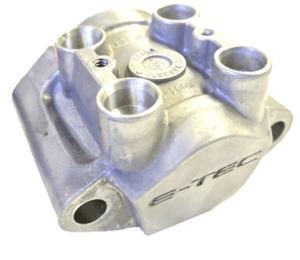

We designed the POWERFLUSH machine using Alibre Design Expert CAD software, and collaborated with our machine shop partners to CNC mill the assembly components from 6061 aluminum. Equipped with a 100 PSI, 90 GPH Weldon Racing pump, proprietary electronics, and a specialized solvent cocktail; it takes fuel injector cleaning to a new level. After traditional ultrasonic cleaning, we perform a POWERFLUSH reverse fuel injector cleaning where we power the injectors in several modes and flow 99% of injectors in reverse to thoroughly dissolve, clean, de-gum and de-varnish and flush inside of the injector.

We observe a difference in injector performance; sometimes marginal, sometimes significant on our injector flow test bench’s after an additional POWERFLUSH step. Especially when dealing with older Port Injectors or GDI types.

- Traditional Procedures

- Our Proprietary Process

- Secret Sauce

- How it Works

- Keeping Cool

- Back Flush is Not Cleaning

Traditional Procedures

When it comes to fuel injection cleaning, traditional ultrasonic cleaning of the injector tips was acceptable but far from optimal. Over time, sediment and plaque can accumulate inside the injector, especially with GDI injectors, which face tougher conditions due to their size and pressure. The usual ultrasonic fuel injector cleaning process involves submerging just the injector tips in an ultrasonic bath to remove carbon and debris from the tip and maybe a bit inside the injector. However, larger particles that can enter from the top tend to settle at the bottom in the injector cavity and can’t make it out through the microscopic pintle spray ports. A quick flush to clear detergent may sometimes help but not always and none of this address’s any buildup inside. In order to properly perform injector testing, used injectors need to be as close to new as possible.

Our Proprietary Process

It’s clear that the key to effectively have your fuel injectors cleaned, you need to run a cleaning solvent through the injector instead of just soaking the tips. The ideal approach is to have the solvent flow in reverse for an extended time, which helps to remove larger particles and buildup, allowing them to exit through the injector’s larger intake opening that they came in through. This method would help keep the injectors cool when powered open.

To tackle this, we’ve completely revamped injector cleaning process everyone uses with our proprietary RedlineInjectors POWERFLUSH cleaning machine. The system features a regulated high-pressure pump that filters fluid down to 5 microns through multiple stages, along with a custom electronics cabinet that safely powers each injector with various circuit protections. POWERFLUSH also includes a fixture assembly with swappable collets and cups that securely holds the injectors and directs high-pressure cleaning fluid through them in reverse.

Secret Sauce

We’re unique in that we created machines specifically designed to reverse clean injectors using a nitrogen-based detergent, which is the strongest option out there for tackling carbon buildup in fuel systems. You can get the base chemical from BASF, it comes in the molecular weight you specify. Then we blend the detergent with a compatible suspension fluid and use it in our POWERFLUSH machine.

How it Works

The POWERFLUSH step is applied after traditional ultrasonic tip cleaning. Our POWERFLUSH machine is designed to completely clean and flush injectors by running fluid through them in reverse under pressure for a lengthy period or as needed while keeping injector body temperatures cool. It has a second phase at the end of high-pressure air back flush. High-pressure air blown in reverse blows out remaining detergent and particles. This results in the cleanest injectors you can achieve. The fluid is pressurized into the tiny spray tip and comes out the larger filter flowing for up to 10 minutes.

Keeping Cool

Injectors are built to have fluid flow through them to keep them cool. With our service, the injectors stay cool to the touch even after 10 minutes of fluid flowing through them. In contrast, during regular ultrasonic tip cleaning, many injectors can heat up dangerously within just 60 seconds, especially HPDI other GDI injectors. That’s why cleaning injectors often takes more time than it should involving short cleaning sessions and multiple clean-and-test cycles. For GDI/Piezo injectors, it often means a lot of time and cycles to do safely which is not an issue with Redline’s fuel Injector servicing. No other shop can clean fuel injectors as quickly and effectively as we do.

Back Flush is Not Cleaning

You might come across some shops talking about flushing with detergent, but what’s really happening is they’re using the same calibration fluid to wash detergent out from the cleaning process for a few seconds. We do that too as one of our steps to prevent cross contamination of cleaning fluid into the testing fluid. It’s called back flushing and usually lasts a few seconds, and it is not detergent. Shops using machines other than ‘Carbon Zapp’ do not have a backflush capability. Even though our machines come with a factory back flush to purge detergent for a few seconds, even that needed some additional engineering, see below.