At Redline Injectors, we use precision-engineered techniques and proprietary products to clean, test, and restore E-TEC injectors – bringing them back to peak factory performance.

For Premium Results Servicing E-TEC Injectors, Choose Redline Injectors!

Proprietary E-TEC Injector Service Features

Redline Injectors is the Industry E-TEC Service Specialists with Proprietary Tools, Components and Cleaning Methods. Whether you need Ski-Doo, Polaris, Bombardier or Evinrude E-TEC injector cleaning and testing we’ve got you covered. If the engine is difficult to start or fails to start, has noticeable fuel odor near the engine, experiences rough idling or engine misfire and runs unevenly during normal operation they need to be serviced. Seized or fouled E-TEC injectors can usually be recovered.

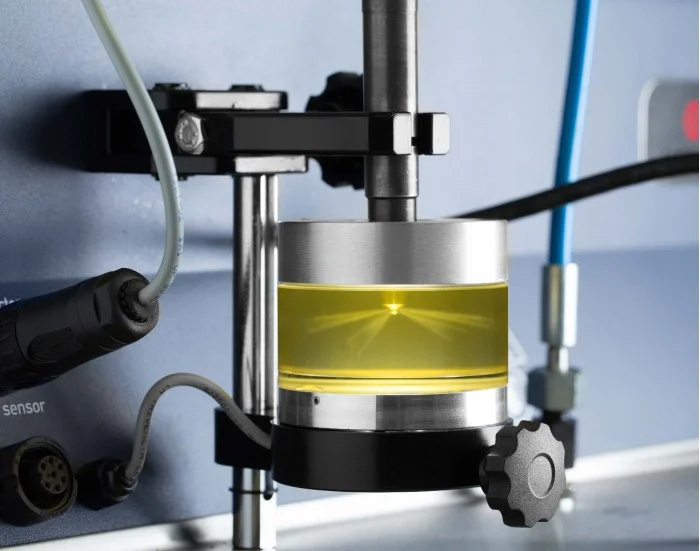

We provide full-service cleaning and testing maintenance for E-TEC injectors with traditional ultrasonic cleaning, our exclusive POWERFLUSH reverse cleaning and dynamic flow testing.

Our standard premium E-TEC injector service always includes all the new parts listed below at a price that’s lower than what most places charge for cleaning alone. See our Port Injector Cleaning and Flow Testing page for service details.

- Correct Internal O-rings, we Manufacture them

- Correct Crush Ring, we Manufacture them

- Correct Filter, we Manufacture them

- Correct Fuel Line Supply and Return O-Rings

Proprietary E-TEC Filters and Crush Rings

The Evinrude Fuel Injector Seal Kit (5007017) no longer includes the filter. While replacement kits from various offshore vendors are available, the filters and crush rings in those kits fail to meet our quality standards. They are always loose and sag compromising filtering capability. That’s why we designed our own high-quality E-TEC filters, O-rings and Crush rings. We now have over 5,000 of our proprietary kits in stock for our service customers.

See the links below for more information:

Redline E-TEC Filters and Crush Rings Designed for Premium Fit and Performance

Redline E-Tec Injector Filters

After trying multiple kits and parts from various vendors, we found that the filters – often priced around $30 – were not only overpriced but also inaccurate. Many of the options on the market come with poorly fitting filters that slide down the injector body, offering no holding tension. This poor fit compromises filtration, leading to repeated pintle clogs and reduced performance.

For this reason, we chose to manufacture E-TEC Filters properly using the original E-TEC filter mold specifications and pass the savings on to our customers.

We provide a complete E-TEC cleaning and testing service with a full complement of in house premium parts at the same price that most shops charge for a cleaning without parts. Plus, you can be assured that the parts will not leave you stranded.

Redline E-Tec Injector Crush Rings

The crush ring is crucial as it ensures the correct clamping force is applied at the interface between the cylinder and injector, creating a secure gas-tight seal. We found aftermarket crush rings sold in filter kits to have a significantly smaller outer diameter and harder material ensuring do not crush. That is an issue.

To solve this additional market gap, we have developed E-TEC 304 stainless steel crush rings that are identical to OEM specifications using the same 304 stainless steel. This contrasts with the harder grade and incorrect inner diameter crush rings that most retailers sell, which do not compress properly. For that reason, we opted to manufacture them correctly and offer savings to our customers.

We provide a complete E-TEC cleaning and testing service with a full complement of in house premium parts at the same price that most shops charge for a cleaning without parts. Plus, you can be assured that the parts will not leave you stranded.

Redline E-TEC Injector O-Rings

We’ve partnered with an O-ring manufacturer to replicate the Viton E-TEC O-rings. Charging customers $15 for just the two larger E-TEC O-rings is excessive, so we had a full set of properly sized E-TEC injector O-rings produced at a fraction of the current retail cost and pass the savings to our customers.

We provide a complete E-TEC cleaning and testing service with a full complement of in house premium parts at the same price that most shops charge for a cleaning without parts. Plus, you can be assured that the parts will not leave you stranded.

E-TEC Injector Cleaning

We create and produce specialized hardware components tailored for retaining and flushing E-TEC injectors on our proprietary POWERFLUSH cleaning machine. Although we do start with a high-powered ultrasonic cleaning, we additionally run E-TEC injectors though our POWERFLUSH which includes a high-powered air flush at the end of the cycle. This additional premium cleaning cycle guarantees the highest level of cleanliness and optimal injector performance. No one cleans these fuel injectors as effectively as we do. Frequently we encounter filters that are damaged and unusable. It is crucial to ALWAYS replace them with properly fitting filters for safety even if they look fine as it’s a matter of time before they start failing.

E-TEC Injector Numbering

The E-Tec Injector has a unique design and implementation. It is essentially a pump. After being manufactured, each injector undergoes thorough testing to determine its precise fuel delivery characteristics. This testing process generates a set of coefficients that indicate the performance of a particular injector. These coefficients are stored in a coefficient file, which contains important data and needs to be uploaded to the Engine Management Module (EMM) for each individual injector.

It is crucial to note that the coefficient file required by the EMM is specific to each injector. If the injector is not reinstalled in its original cylinder location and the corresponding coefficient file is not used, the EMM will not be able to properly control the injector. This can potentially lead to engine damage or poor running performance. Therefore, it is essential to track the injector to its cylinder number and reinstall them in the same way to ensure optimal functionality.

*In other words, every E-tec injector needs to be returned to the exact cylinder it was taken from. See the Service Manual*

Prior to shipping your E-TEC injectors, please number the cylinder with a SHARPIE or similar for your benefit, we will then etch the injector and the manifold for you before we begin work if you have not done so already.

Service Exclusions

- We do not Service Diesel Injectors.

- We do not provide service for GM CPI/SCPI Spider injectors.

- We no longer provide service for FICHT injectors at this time.

- See our Injector ID Page for visual references.

Shipping and Service FAQs

Service Related Questions

Our standard injector service includes an additional POWERFLUSH cleaning stage for Top Feed, Side feed, E-TEC, Optimax Air, GDI and Piezo Injectors.

Yes, we have a 2 injector minimum.

Absolutely! Rest assured that we will take care of removing the injectors for you for (typically GDI and side feed) and invoice you for a bench fee of $10 per rail to do the work as problems can often arise. However, it’s important to note that we cannot be held responsible for any potential damage that may occur during the removal process. To ensure a smooth experience, we recommend that you personally remove the injectors from the rail.

To avoid any issues with shipping service secure them in plastic and tape them to prevent leaks.

For your convenience, side feed injectors will be re-installed in the fuel rails, top feed and GDI injectors will be packaged separately. GDI Injector clips are very easy, you’ll have no issues, but they are tricky to get off which we will do if you wish.

- Service prices and options are posted in store per item type as well as on the pricing page. Service Pricing

- Please check the Injector id injectors page on the menu if your unsure what you have. Injector ID

Turn around times are stated on the Home page.

Shipping Related Questions

For local service contact us though the contact form. Generally orders for pick up / drop off service are:

- Ordered through the web site for credit cars purchases, we will refund shipping if there is any applied.

- Dropped off with contact details of name, email and phone number, cash payment on pick up is fine.

- Shipping insurance up to $100 is automatically provided.

- To add Shipping additional Insurance, please select amount coverage you’d like using the “Shipping Insurance” line item before checkout.

- Additional shipping insurance is calculated for you based on $1.60 per $100 of declared value.

- Please insure items based on their actual replacement value, extra insurance above the value will accomplish nothing, claims are on shipment value, not amount of insurance bought.

- Insurance applies only to the item we’re returning to you.

If you would like expedited shipping contact us at [email protected] for separate invoicing for those charges. Once the items are packaged and ready to ship we will send a separate invoice for the chares based on the option you specified.

Remember to enclose a copy of the “order receipt “inside the package you are sending to us.

We accept shipments from UPS, USPS, Fedex or DHL to following address 7 days a week.

Sending UPS is the optimal choice within the US, however.

Redline Injectors

3036 HIGHWAY 35

Box #227

Hazlet, NJ 07730

Remember to enclose a copy of the “order receipt “inside the package you are sending to us.

When preparing the injectors for shipping, it is strongly advised to place them inside a regular zip lock bag first. This will help to keep the fuel smell contained. It is important to avoid any damage during transit, so make sure not to simply toss the bag into a box without any additional packing material. This is particularly crucial for the pintle end.

It is not recommended to ship the injectors in a bubble envelope. Optimal protection can be achieved by using a box with some padding or a bubble envelope in a box. The small flat rate box from the Post Office may be good budget-friendly option for smaller injectors.