- At Redline Injectors, we do things differently. Traditional cleaning methods dating back to 1989, use mostly water and lightly dissolve tip deposits, leaving stubborn internal buildup and restrictions untouched.

- Our TrueFlow Bench, Ultrasonic and POWERFLUSH machine all use a proprietary injector safe solvent cocktail to achieve unmatched fuel injector cleaning from the inside out.

- Restore maximum power and OEM-level performance with our injector service – For fuel injector cleaning and flow testing, go with Redline Injectors!

Premium Cleaning and Dynamic Testing of Port Injectors

Overview of our Premium Port Fuel Injector Cleaning

From automotive to marine applications, whether your injectors are dirty or clogged, our premium port injector cleaning and flow testing involves comprehensive static and dynamic flow testing performed both before and after cleaning and includes all replacement parts.

We do not offer testing-only, cleaning-only services nor do we offer a no parts option or sell parts for that matter. We provide a single, premium service. Where compromise ends, premium begins. Don’t settle for less go with Redline Injectors!

At Redline Injectors, we do not believe in “doing things the they are done because it’s always been done that way”.

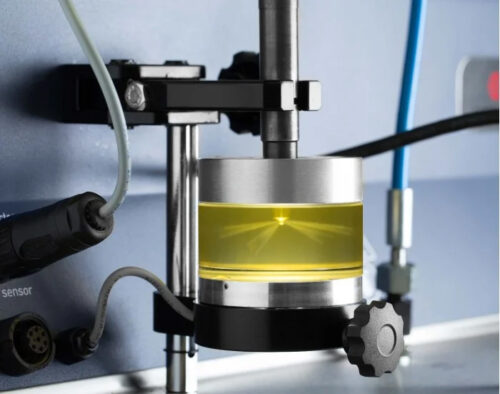

We use a proprietary waterless blend of 100% polar and non-polar solvents we call TrueFlow. Our solvent selection is safe enough for cleaning electromagnetic coils and electronic circuitry, yet powerful enough to dissolve varnish on contact. This approach is significantly more costly, took months testing and analysis to perfect along with a year of CAD design and CNC manufacturing of prototypes for the final equipment but the results proved to be well worth it.

We perform a basic electrical and pulse checks on each injector before beginning service using Multimeter.

If an injector is found to be permanently defective BEFORE we begin cleaning and testing, we will not proceed with the service. Instead, we’ll issue a refund for the injector’s cost, there is a $0 bench fee.

The injectors exterior is then ultrasonically cleaned in a mild heated detergent for one minute to remove external contaminants to prevent cross contamination. A low-pressure air flush clears any remaining solution.

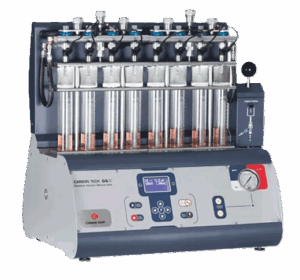

Baseline fuel injector testing is performed on our Carbon Zapp GS8 Port Injector machine. Each injector is flow-tested to evaluate performance, checking for leaks, blockages, spray pattern issues, and volume accuracy.

All serviceable components including filters, pintles, O-rings, seals, spacers, clips, and grommets are then carefully removed from the injector body and the injector is stripped.

Each injector is filled with yet another proprietary concentrated solvent solvent and tips are plunged into the solvent and pulsed on our proprietary injector bench. This ensures the solution penetrates every internal passage, all the way to the nozzle tip. This process runs for 5 minutes, allowing varnish and lacquer deposits to fully dissolve inside the injector. A final high-pressure air flush then removes any remaining solvent and loosened debris.

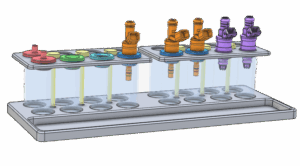

We accounted for the full range of injector form factors and designed and had machined custom collets to fit Top Feed, Side Feed, GDI, and Piezoelectric injectors for use on our Injector Bench.

*This does not apply to E-TEC injectors.

We apply our unique fuel injector ultrasonic cleaning process using our proprietary Ultrasonic plate, injector adapter inserts and Trueflow cleaning solution heated to 130F in our German-engineered Elma ultrasonic machines. This applies to E-TEC injectors as well.

Every top-feed and side-feed port injector as well as GDI injectors receive this treatment at minimum. During this process, N-Heptane is pressurized and backflushed through the injector while it is pulsed, dislodging and removing trapped debris. The material that comes out is often described as resembling fine black pepper specks and occurs 30% of the time.

*This does not apply to E-TEC injectors.

If baseline injector testing shows an injector is especially stubborn, they are backflushed in reverse at on our proprietary POWERFLUSH machine at high pressure for up to 10 minutes in reverse, from the tiny discharge end then out supply end while upside down.

We do not pulse the injectors, rather we open them like a hose ensuring maximum flow. In our POWERFLUSH, we utilize the same TrueFlow solvent blend and heated to 105 F. This forces out any remaining debris, dissolved or gummy varnish, lacquer and ethanol plaque.

This step is critical for problem injectors; many contaminants are simply too large or sticky and gummy to exit through the tiny nozzle discharge opening.

*For E-TEC injectors, this is used rarely and only as a last resort.

Final injector testing is performed on our Carbon Zapp GS8 Port Injector machine. Each injector is again flow-tested to evaluate performance, checking for leaks, blockages, spray pattern issues, and volume accuracy.

Each injector undergoes a final injector flow test on our Carbon Zapp GS8 test bench to evaluate performance. A consolidated report is then generated using our custom software.

As part of our standard premium service, you will receive new fuel injector components, including filters, O-rings, seals, caps, grommets, clips, spacers, decouplers, clamps, ferrules, caps and hoses, with OEM options generally available for all injector types.

On rare occasions an injector still shows issues at this stage, it is mechanical fatigue or wear.

Port Fuel Injector Flow Testing

We use the latest Carbon Zapp GS8 for all port fuel injector flow testing to determine if they are operating within the required tolerances as well as electrical resistance, short circuit & open circuit test. Our standard port injector flow testing always include BOTH Static and Dynamic tests on injectors that support both.

For E-TEC injectors, we’ve developed specialized test plates that allow us to evaluate up to three injectors simultaneously.

All seals, O-rings, filters, and related components are included as part of our standard service. A standard injector report is generated for these types of injectors and are electronically delivered to your email.

Key Topics For Port Injectors

Difference Between Dynamic and Static Injector Testing

What are Signs of Clogged Fuel Injectors and How to Fix Them?

How often should I have fuel injectors cleaned and why?

Can Ethanol Damage Fuel Injectors

How To Test Fuel Injector Coils

Service Exclusions

- We do not service Diesel Injectors

- We do not service CPI/SCPI Spider injectors

- We do not service FICHT injectors

- We do not service Flux Capacitors

- See our Injector Type Page for visual references

Shipping and Service FAQs

Service Related Questions

We do not rebuild injectors—they are not rebuildable. We clean, test them and report on the results. No warranty applies. However, injectors can occasionally stick if left sitting after cleaning, even though we oil them to help prevent this. If your injectors are stuck, or if you experience any issues not noted on your injector report after receiving them back, please contact us.

Our standard injector service includes an additional POWERFLUSH cleaning stage for Top Feed, Side feed, E-TEC, Optimax Air, GDI and Piezo Injectors. This will be applied automatically to injectors that are struggling to flow despite appearing to be in otherwise normal condition.

Yes, we have a 2 injector minimum.

Absolutely! Rest assured that we will take care of removing the injectors for you for (typically GDI and side feed) and invoice you for a bench fee of $10 per rail to do the work as problems can often arise. However, it’s important to note that we cannot be held responsible for any potential damage that may occur during the removal process. To ensure a smooth experience, we recommend that you personally remove the injectors from the rail.

To avoid any issues with shipping service secure them in plastic and tape them to prevent leaks.

For your convenience, side feed injectors will be re-installed in the fuel rails, top feed and GDI injectors will be packaged separately. GDI Injector clips are fairly easy to remove, you should not have no any issues, but if yours are tricky to remove we will can do it if you wish.

- Service prices and options are posted in store per item type as well as on the pricing page. Service Pricing

- Please check the Injector id injectors page on the menu if your unsure what you have. Injector ID

Shipping Related Questions

For local drop/pick up service check the “Local Drop-Off” box on the order form.

Once order is places, email us at [email protected] for drop off instructions.

- Shipping insurance up to $100 is automatically provided.

- To add Shipping additional Insurance, please select amount coverage you’d like using the “Shipping Insurance” line item before checkout.

- Additional shipping insurance is calculated for you based on $1.60 per $100 of declared value.

- Please insure items based on their actual replacement value, extra insurance above the value will accomplish nothing, claims are on shipment value, not amount of insurance bought.

- Insurance applies only to the item we’re returning to you.

If you would like expedited shipping contact us at [email protected] for separate invoicing for those charges. Once the items are packaged and ready to ship we will send a separate invoice for the chares based on the option you specified.

Include your Name on a card or paper inside the shipment box as the shipping label sometimes gets obscured.

We accept shipments from UPS, USPS, Fedex or DHL to following address 7 days a week.

Sending UPS is the optimal choice within the US, however.

Redline Injectors

3036 HIGHWAY 35 #227

Hazlet, NJ 07730

Include your Name on a card or paper inside the shipment box as the shipping label sometimes gets obscured.

When preparing the injectors for shipping, it is strongly advised to place them inside a regular zip lock bag first. This will help to keep the fuel smell contained. It is important to avoid any damage during transit, so make sure not to simply toss the bag into a box without any additional packing material. This is particularly crucial for the pintle end.

It is not recommended to ship the injectors in a bubble envelope. Optimal protection can be achieved by using a box with some padding or a bubble envelope in a box. The small flat rate box from the Post Office may be good budget-friendly option for smaller injectors.