t

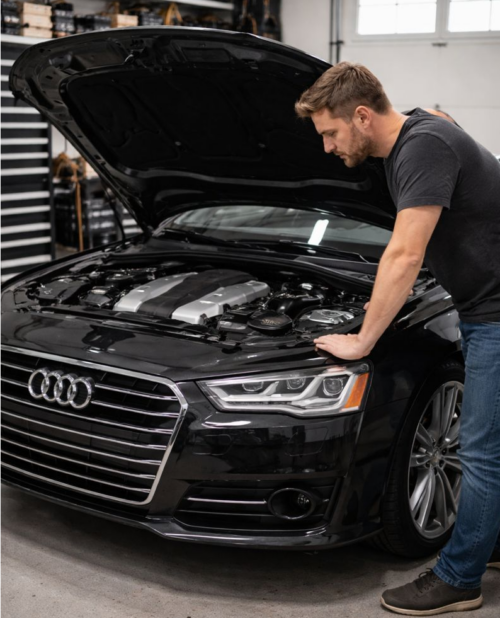

- At Redline Injectors, we do things differently. Traditional cleaning methods dating back to 1989, use mostly water and lightly dissolve tip deposits, leaving stubborn internal buildup and restrictions untouched.

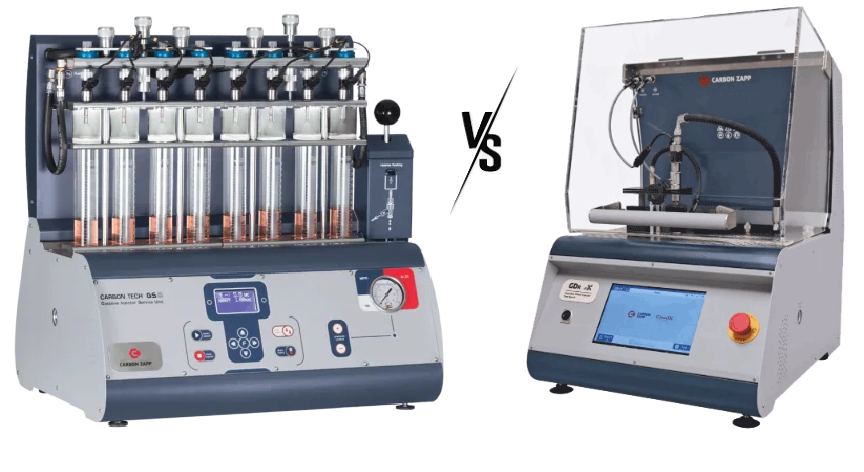

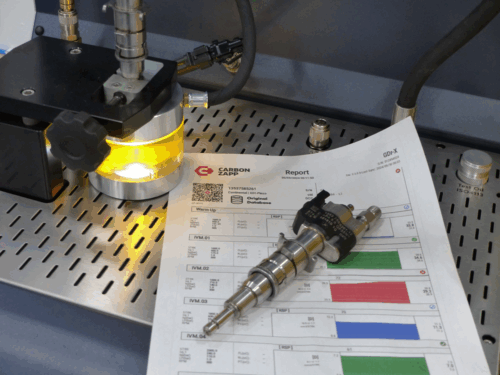

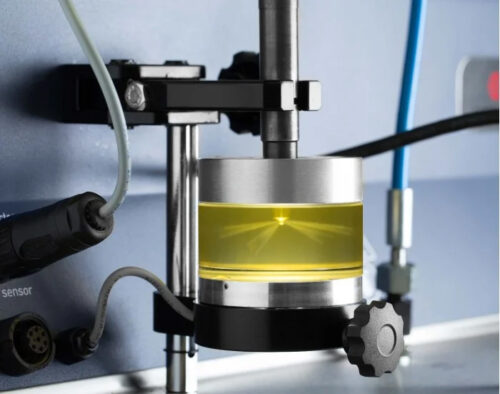

- Our TrueFlow Bench, Ultrasonic and POWERFLUSH machine all use a proprietary injector safe solvent cocktail to achieve unmatched fuel injector cleaning from the inside out.

- Restore maximum power and OEM-level performance with our injector service. Where compromise ends, premium begins. Don’t settle for less, go with Redline Injectors!