- We take pride in providing a premium injector service that goes above and beyond. As the market leader in premium injector services, we offer expert Fuel Injector Cleaning and Testing with unmatched precision and quality.

- Redline Injectors, founded and run by engineers, constantly challenged traditional processes. When improved tools, chemicals, or processes didn’t exist, we invented them; redefining injector cleaning.

A Different Kind Of Injector Service Shop

An Engineering-Based Approach To Fuel Injector Service

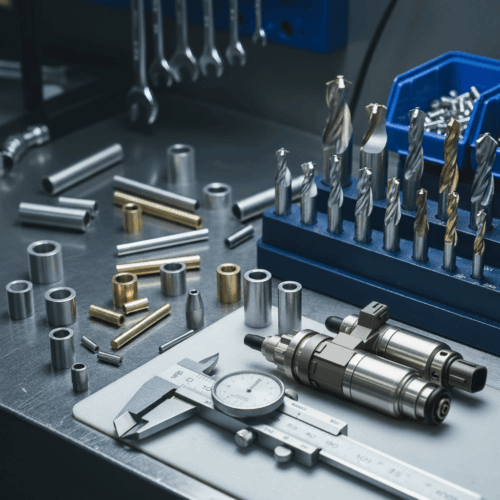

Aside from the test machines, traditional injector servicing methods, chemicals, and tooling were mostly ineffective; and proper tools often didn’t exist. Even basic tasks like installing filters or removing E-TEC pintles are done with mallets and vise grips. So we invented all those. You can see many of them on our YouTube page.

Redline Injectors was founded and run by engineers, built on a commitment to quality and an engineering-first approach. We use multiple purpose-built test machines, each optimized for specific injector types, because no single machine can handle them all. When existing tools and chemicals fall short, we design and manufacture our own to meet unique needs and create new processes using them where none previously existed.

You won’t find us using vice grips, hammers, or improvised tools. If the right equipment doesn’t exist, we build it.

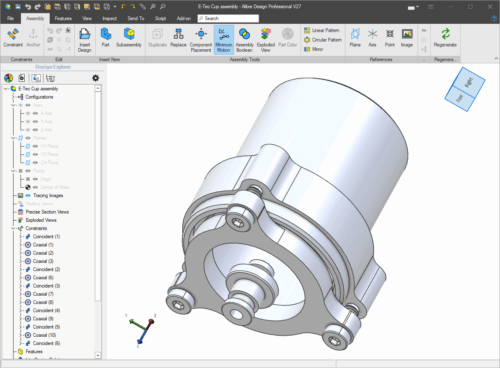

It All Starts With Good Design

We leverage decades of CAD design experience because precision matters. Every tool begins as a digital sub-assembly, perfected virtually to test dimensions, variations, and performance before production. This process eliminates guesswork, reduces errors and waste, and ensures each design is manufactured exactly as intended. Often, we produce multiple tool variants to fit different injector form factors.

Cost is never a deciding factor; if a tool is needed, it should exist. That’s our guiding principle.

Our Equipment and Partners

We Exclusively Use Fuel Injector Test Benches From

We are based in New Jersey, where we proudly source the latest Carbon Zapp Multi-Port and GDI & Piezoelectric testing equipment and Elma ultrasonic machines directly from the manufacturers. For our proprietary tooling and equipment design we source machine shop services from top-tier vendors whether CNC billet aluminum or SLS 3D glass filled 3D printing is required, this ensures the manufacture of our proprietary equipment and tooling from our CAD design files adheres to the highest industry standards.