Regarding E-TEC Injector Injector Flow Post Cleaning immediately after ultrasonic cleaning, then increasing hours to days later, typically occurs due to the movement and resettlement of internal debris or atmospheric factors.

Reasons for E-TEC Flow Decrease Post Cleaning then Increase Later in time:

- Gradual Flushing: As the engine is driven, the constant high-pressure fuel flow through the injector eventually washes away the residual debris that was loosened but not removed during the initial cleaning.

- Chemical Dissolution: Modern fuels contain detergents that continue to work on any remaining softened deposits that the ultrasonic bath didn’t completely dissolve, leading to improved flow over several hundred miles.

- Mechanical Reseating: Over several days of operation, the moving parts (pintle and spring) reseat themselves and return to their optimal operating temperature and lubrication state, restoring full movement.

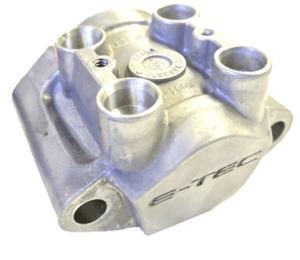

- The big one: E-TEC injectors operate as high-pressure pumps rather than conventional injectors and contain a substantial amount of metal that must be properly heat-soaked. In E-TEC systems, pre- and post-cleaning flow numbers frequently vary due to temperature-related factors, including injector, manifold, air, test fluid, coil temperatures and especially nozzle template designed to sit against the cylinder head. While flow measurements may be highly consistent within a single test session (e.g., across four consecutive runs), those values can shift and establish a new; but equally consistent; baseline after time has passed, such as an hour later and different yet again the following morning. We can observe flow variances of up to 10 cc with the same set of injectors left connected on the test bench, with no changes other than the passage of time along with injector and temperature changes.

- Key Takeaway: Because of this inherent E-TEC variability, post-test flow numbers are not a definitive measure of injector cleaning effectiveness. The true measure is injector performance under real engine operating conditions, which are managed by the EMM and cannot be accurately replicated on a cold test bench.

These explanations clarify the phenomenon of E-TEC fuel injectors exhibiting reduced flow post-ultrasonic cleaning, which typically increases hours or days later.